Maximizing Power Generation Efficiency with Tadpole Gasket Tape

In power generation systems—whether fueled by diesel, natural gas, or renewable sources—maintaining the integrity of exhaust and plenum components is essential for efficient performance and safety. Exhaust manifolds, plenums, and ductwork operate under extreme heat and pressure, where even small leaks can lead to energy loss, reduced output, or equipment damage. Tadpole gasket tape is a reliable high-temperature sealing solution that significantly improves the efficiency and durability of these critical components.

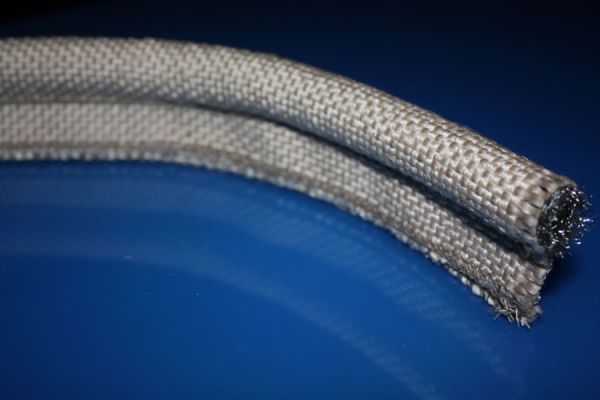

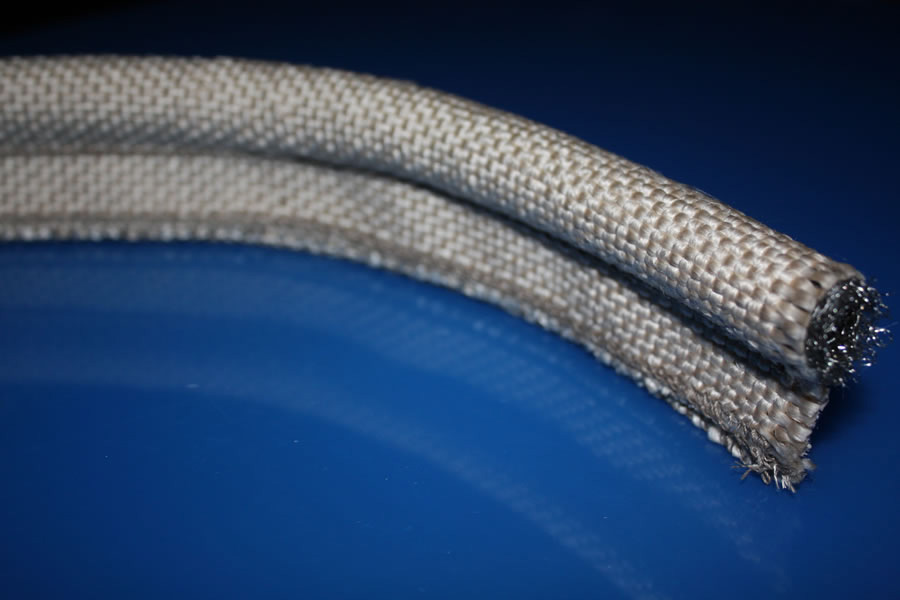

Tadpole gasket tape features a rounded, compressible bulb and a flat tail that securely fastens to surfaces, creating a tight, long-lasting seal. Made from heat- and chemical-resistant materials like silicone-coated fiberglass, it can withstand the intense conditions commonly found in exhaust and plenum assemblies. It’s commonly installed at access ports, flanges, or seams where thermal expansion and vibration could otherwise compromise the seal.

By preventing leaks in exhaust systems, tadpole gasket tape ensures optimal backpressure and efficient routing of combustion gases—key to maintaining engine performance and reducing emissions. In plenum chambers, the tape helps contain and direct airflow with precision, promoting balanced distribution and improving thermal efficiency. This leads to better system output, reduced maintenance needs, and lower operational costs.

Incorporating tadpole gasket tape into the sealing strategy for power generation equipment is a smart move for facility managers and OEMs alike. It’s a cost-effective upgrade that enhances system reliability, protects vital components from heat and wear, and supports cleaner, more efficient energy production—an essential goal in today’s performance-driven and sustainability-conscious energy sector.