Improving Pulp & Paper Hatch Efficiency with Tadpole Gasket Tape

In the pulp and paper industry, maintaining process efficiency and safety is paramount—especially in high-temperature, high-moisture environments. Equipment hatches on digesters, recovery boilers, and processing vessels must seal tightly to prevent steam and chemical vapors from escaping. One of the most effective ways to ensure a secure and long-lasting seal is by using tadpole gasket tape. This specialized tape helps improve the performance and energy efficiency of pulp and paper hatch systems.

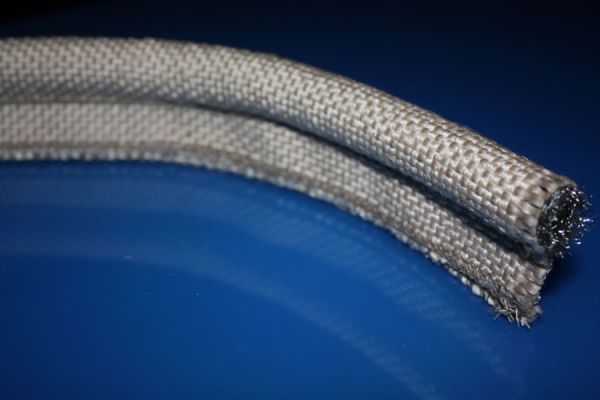

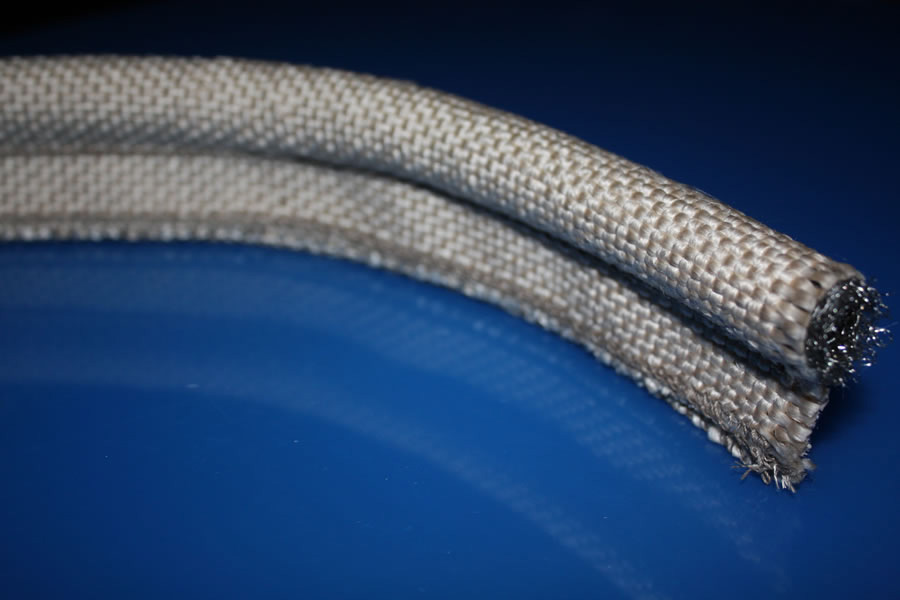

Tadpole gasket tape features a compressible bulb and a flat tail, allowing it to form a tight seal even on irregular surfaces or doors that are opened frequently. Made from durable, heat- and chemical-resistant materials such as silicone-coated fiberglass, this gasket tape withstands the extreme temperatures, steam pressure, and corrosive chemicals often present in pulp and paper operations. Its design allows it to conform easily to hatch frames, creating a flexible and resilient barrier.

By sealing hatches effectively, tadpole gasket tape helps retain heat and pressure within process vessels, reducing energy loss and maintaining optimal process conditions. This not only improves overall system efficiency but also minimizes emissions and ensures a safer work environment by preventing the release of hazardous vapors. The enhanced seal also reduces wear on equipment and lowers the frequency of maintenance due to gasket degradation or leakage.

For mills looking to improve uptime and reduce operational costs, tadpole gasket tape offers a simple yet powerful upgrade. It enhances hatch performance, extends gasket life, and supports the demanding conditions of pulp and paper processing. Investing in high-quality sealing solutions like tadpole gasket tape is a smart step toward more reliable and energy-efficient plant operations.