Improving Power Generation Exhaust and Plenum Efficiency with Tadpole Gasket Tape

In the power generation industry, maintaining efficiency and reliability is critical—especially in systems that manage high-temperature exhaust and airflow through plenums. These components must operate under intense thermal and mechanical stress, where even minor leaks can lead to energy loss, pressure imbalances, and reduced system performance. Tadpole gasket tape offers a proven sealing solution that enhances the efficiency, safety, and longevity of both exhaust and plenum assemblies.

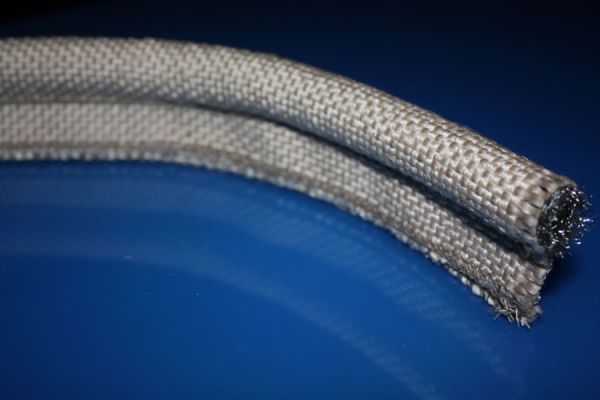

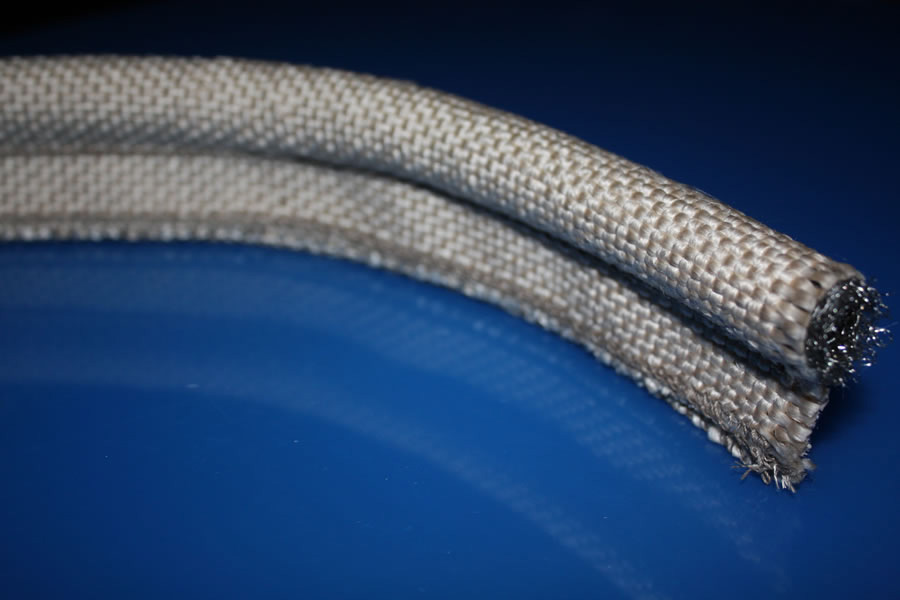

Tadpole gasket tape is designed with a compressible “bulb” that forms a tight seal when compressed, and a “tail” that anchors it securely to doors, flanges, and access points. Made from high-temperature-resistant materials like silicone-coated fiberglass, this tape performs exceptionally well in demanding environments, tolerating extreme heat, vibration, and repeated thermal cycling. Its flexible design allows it to conform to uneven surfaces—perfect for sealing large ductwork and access panels found in power generation facilities.

By eliminating leaks in exhaust pathways and air plenums, tadpole gasket tape helps maintain optimal pressure and temperature levels within the system. This ensures more efficient combustion, better airflow regulation, and reduced stress on fans, dampers, and other mechanical components. The improved seal also prevents the escape of hot gases and contaminants, enhancing safety and supporting compliance with emissions regulations.

Integrating tadpole gasket tape into exhaust and plenum systems is a simple yet powerful upgrade that pays off in both performance and cost savings. It extends the life of system components, reduces energy waste, and supports smoother, more efficient power generation—whether the facility runs on fossil fuels, biomass, or other energy sources.