Improving Furnace Seal Efficiency with Tadpole Gasket Tape

Furnaces operate under intense heat and require airtight seals to maintain consistent temperatures and ensure safety. One of the most effective ways to improve furnace performance and energy efficiency is by using tadpole gasket tape. This high-temperature sealing solution is specifically designed to withstand the extreme conditions inside industrial furnaces, helping reduce heat loss, maintain temperature uniformity, and extend the life of critical components.

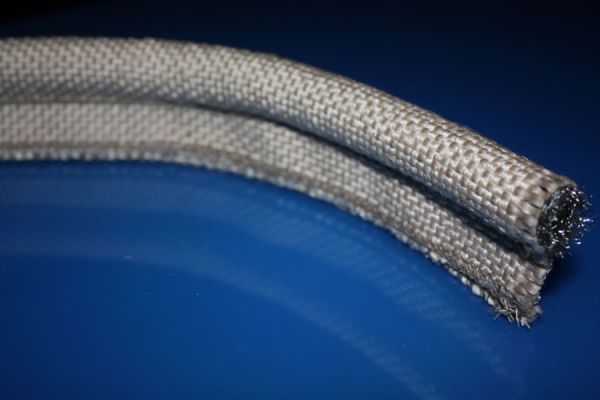

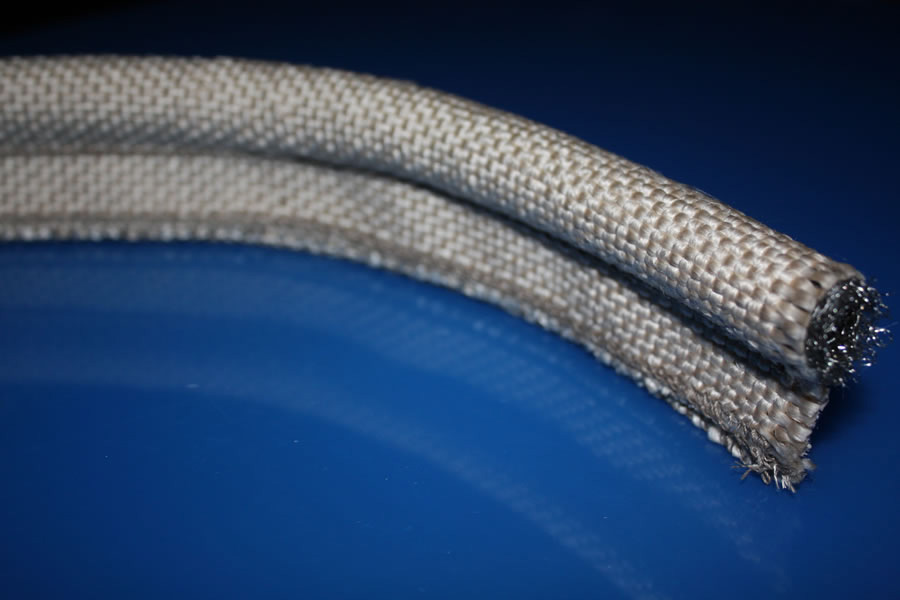

Tadpole gasket tape features a distinctive design—a rounded “bulb” that compresses to form a seal, and a flat “tail” that attaches securely to the furnace structure. Made from heat-resistant materials such as fiberglass or silicone-coated fabrics, the tape provides a flexible, durable seal that can handle the repeated thermal cycling and mechanical stress typical in furnace operations. It’s commonly applied around access doors, observation ports, or other seams where heat might escape.

By minimizing heat leakage, tadpole gasket tape enhances thermal efficiency and reduces the amount of energy required to maintain operating temperatures. This leads to more stable furnace conditions, shorter cycle times, and lower fuel or electricity costs. A tighter seal also prevents outside air from entering the furnace chamber, which is critical for processes that rely on specific atmospheric conditions or where oxygen intrusion can affect product quality.

Whether used in heat-treating, metal forging, or ceramic firing, upgrading to tadpole gasket tape can significantly improve furnace performance. It’s a simple yet powerful solution that helps manufacturers reduce waste, lower energy bills, and maintain safe, reliable furnace operation—making it a smart investment for any high-temperature processing environment.