Improving Exhaust Silencer Efficiency with Tadpole Gasket Tape

Exhaust silencers play a critical role in reducing noise and controlling emissions from industrial engines, generators, and process systems. To function effectively, these silencers must maintain a tight seal to contain high-temperature exhaust gases and prevent leaks that can reduce performance or compromise safety. Tadpole gasket tape is a highly effective sealing solution that enhances the efficiency and reliability of exhaust silencers, particularly in high-heat and vibration-prone environments.

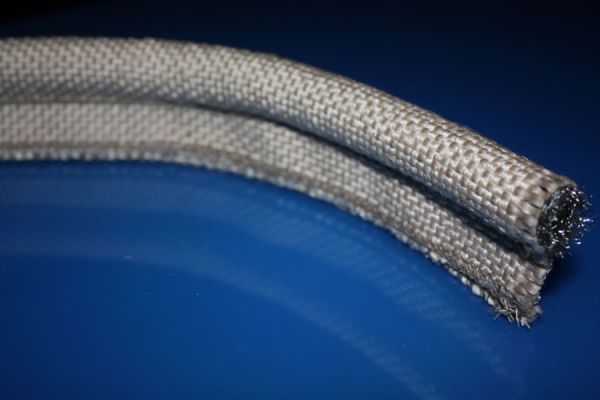

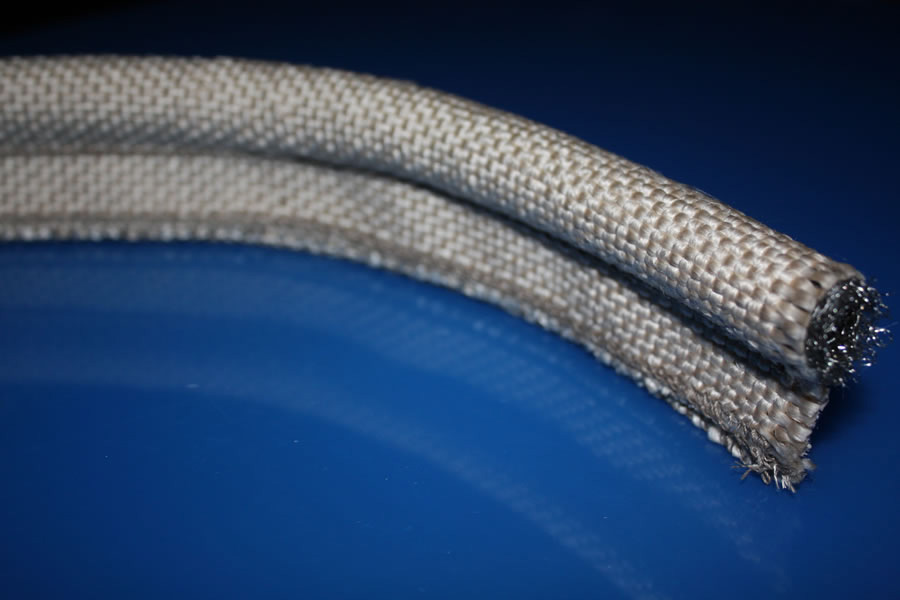

Tadpole gasket tape is designed with a compressible “bulb” that creates a strong seal and a “tail” that anchors it to flanges, access panels, or junctions within the exhaust system. Made from heat-resistant materials such as silicone-coated fiberglass or high-temperature textiles, this gasket tape is built to endure extreme exhaust temperatures and mechanical stress. Its flexible construction allows it to conform to irregular surfaces and maintain a consistent seal despite thermal expansion or vibration.

By eliminating gaps and preventing gas leaks, tadpole gasket tape improves the silencer’s ability to control both noise and emissions. A secure seal also reduces backpressure variations, which can lead to inefficiencies in engine performance or increased wear on system components. Maintaining a stable exhaust flow not only supports optimal sound attenuation but also enhances the overall durability and effectiveness of the entire exhaust system.

For facilities that depend on reliable exhaust management—such as power plants, manufacturing sites, and marine operations—incorporating tadpole gasket tape is a smart and cost-effective upgrade. It delivers a better seal, extends silencer lifespan, and ensures compliance with noise and emission standards, all while supporting smoother, more efficient system operation.