Improving Conveyor Oven Efficiency with Tadpole Gasket Tape

In the world of industrial heating, conveyor ovens play a critical role in continuous processes like baking, curing, drying, and heat-treating materials. Efficiency in these systems is key—not only to maintain product consistency, but also to reduce operating costs. One often overlooked component that significantly impacts performance is the oven’s sealing system. Tadpole gasket tape is a proven solution that helps conveyor ovens operate more efficiently by reducing heat loss and ensuring consistent internal temperatures.

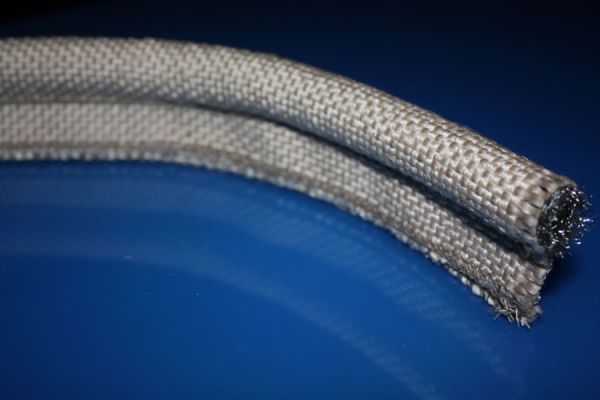

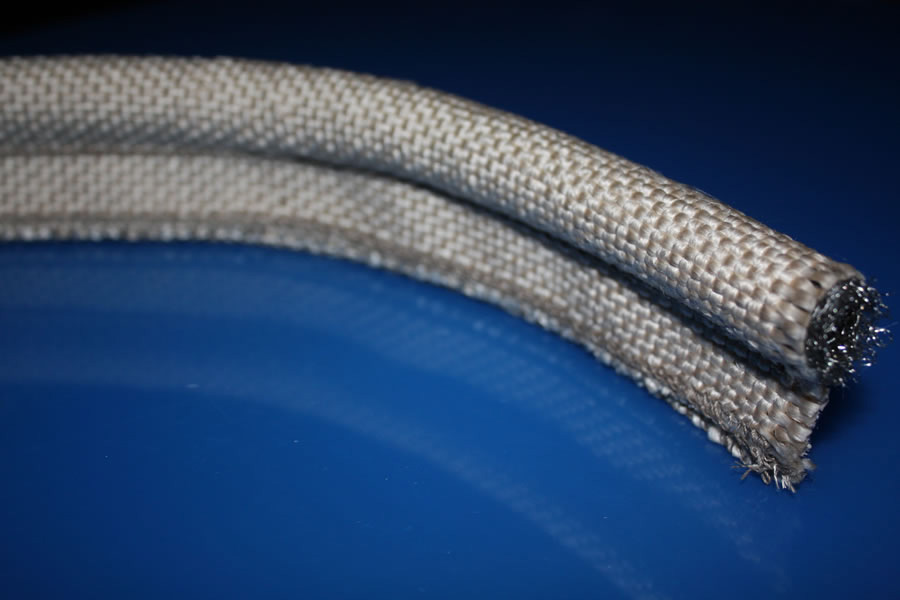

Tadpole gasket tape is uniquely designed with a rounded “bulb” that compresses to form a tight seal and a “tail” that’s secured to the oven structure. It’s made from heat-resistant materials like fiberglass, silicone-coated fabrics, or other high-temp textiles capable of withstanding the extreme environments inside conveyor ovens. The gasket is typically installed around oven doors, access panels, or where conveyor belts enter and exit the heated chamber. These points are common sources of thermal leakage, and tadpole gaskets help prevent that loss.

By maintaining a better seal, conveyor ovens experience fewer temperature fluctuations, which leads to faster heat-up times, improved product throughput, and lower energy consumption. This tight seal also helps reduce wear and tear on heating elements and internal components by stabilizing operating conditions. For production lines that run continuously, even a modest improvement in thermal retention can translate into substantial cost savings over time.

Incorporating tadpole gasket tape into a conveyor oven is a relatively simple upgrade with outsized benefits. It enhances thermal performance, supports process consistency, and extends equipment life—all while improving energy efficiency. For any facility looking to optimize its heat-processing equipment, upgrading the oven seal with high-quality tadpole gasket tape is a smart and durable investment.