Enhancing Soil Contamination Equipment Efficiency with Tadpole Gasket Tape

Soil contamination equipment—used for processes like thermal desorption, vapor extraction, and soil remediation—must operate under controlled conditions to effectively remove pollutants such as hydrocarbons, heavy metals, and volatile organic compounds (VOCs). Maintaining a sealed system is critical to ensure contaminants are properly contained and processed. Tadpole gasket tape offers an ideal sealing solution, helping make soil contamination equipment more efficient, reliable, and environmentally safe.

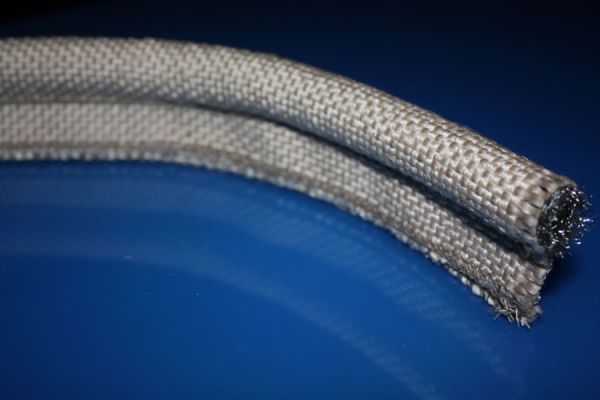

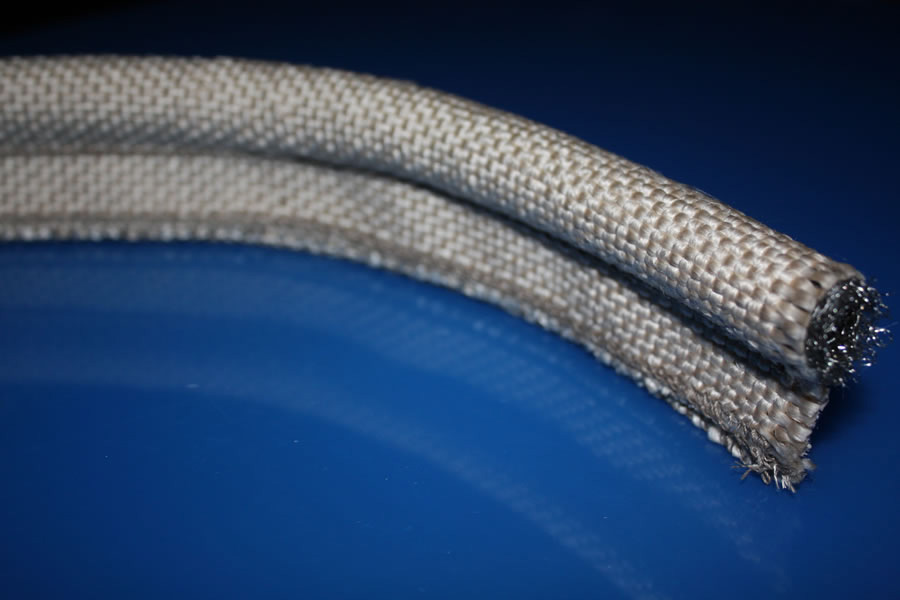

Tadpole gasket tape features a compressible bulb and an anchoring tail, designed to form a tight, heat-resistant seal around access doors, flanges, and inspection ports. Constructed from high-performance materials like silicone-coated fiberglass or other high-temperature textiles, this tape is built to withstand the elevated temperatures and harsh chemical environments often present in soil remediation systems. Its flexibility allows it to conform to irregular surfaces, maintaining an airtight seal even under thermal cycling and vibration.

By preventing leaks of hazardous vapors or gases, tadpole gasket tape improves the containment and treatment of contaminated materials. This not only enhances the effectiveness of the remediation process but also reduces the risk of releasing untreated pollutants into the environment. Additionally, a well-sealed system requires less energy to maintain operating temperatures, resulting in improved thermal efficiency and lower operational costs.

For environmental remediation contractors and industrial operators, integrating tadpole gasket tape into soil contamination equipment is a smart investment. It helps maintain regulatory compliance, supports process consistency, and extends the lifespan of critical system components. Whether used in mobile or stationary setups, this sealing solution contributes directly to safer, cleaner, and more efficient soil treatment operations.