Enhancing Heat Treating Efficiency with Tadpole Gasket Tape

Heat treating processes—such as annealing, tempering, and hardening—require precise temperature control and airtight environments to ensure consistent metallurgical results. Any heat loss or air leakage during these processes can compromise part quality, increase cycle times, and waste energy. That’s why tadpole gasket tape is a key component in improving the efficiency and reliability of heat treating equipment. It provides a durable, high-temperature seal that supports consistent performance in even the most demanding applications.

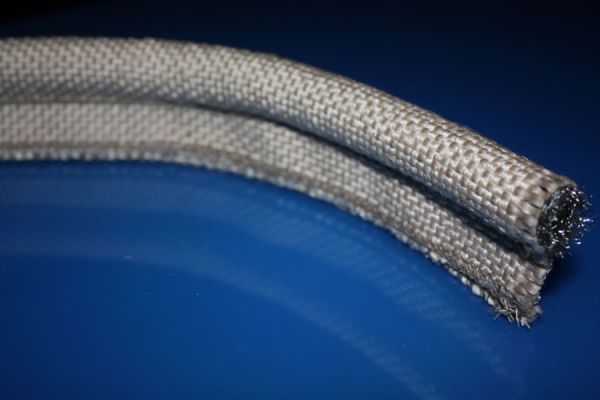

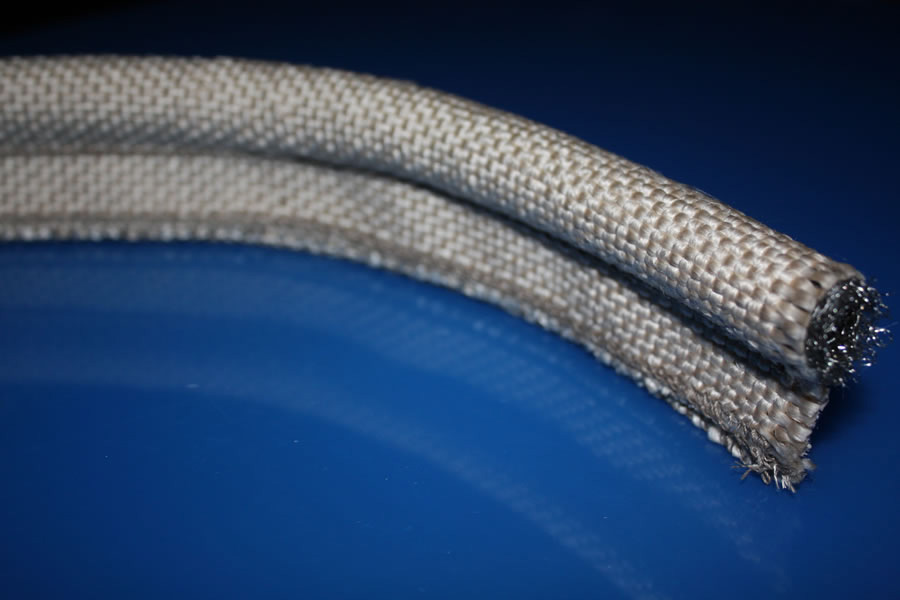

Tadpole gasket tape is constructed with a compressible “bulb” and a flat “tail” for secure installation on oven doors, access panels, and furnace flanges. Made from heat-resistant materials like fiberglass or silicone-coated fabrics, it is designed to withstand the extreme temperatures—often exceeding 1000°F—encountered in industrial heat treating environments. The tape maintains flexibility and resilience through repeated thermal cycling, ensuring a tight seal over long-term use.

By sealing potential leakage points, tadpole gasket tape helps maintain stable internal temperatures and controlled atmospheres—both critical for proper heat treatment. This reduces heat loss, minimizes energy consumption, and allows equipment to reach target temperatures more quickly and efficiently. The result is shorter cycle times, lower fuel or electricity costs, and improved product consistency.

For facilities focused on precision and throughput, upgrading or replacing worn seals with high-quality tadpole gasket tape is a smart and cost-effective move. It enhances thermal performance, supports process control, and extends the service life of critical heat treating equipment—delivering measurable benefits across the entire operation.