Enhancing Fume Incinerator Efficiency with Tadpole Gasket Tape

Fume incinerators play a vital role in controlling air pollution by safely burning off volatile organic compounds (VOCs), hazardous gases, and other airborne pollutants. For these systems to operate effectively, they must maintain extremely high internal temperatures while preventing the escape of harmful emissions. One key component that helps achieve this is tadpole gasket tape—a high-temperature sealing solution that significantly improves the efficiency and safety of fume incinerators.

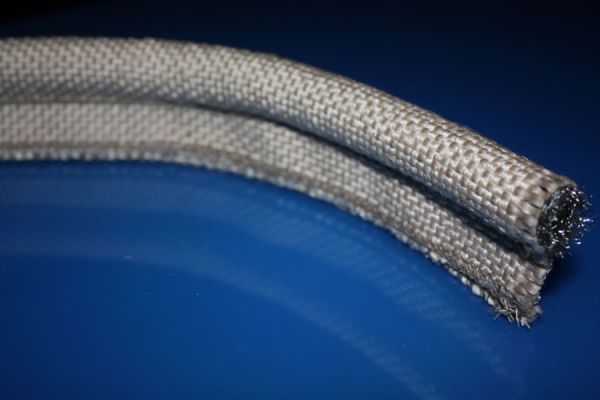

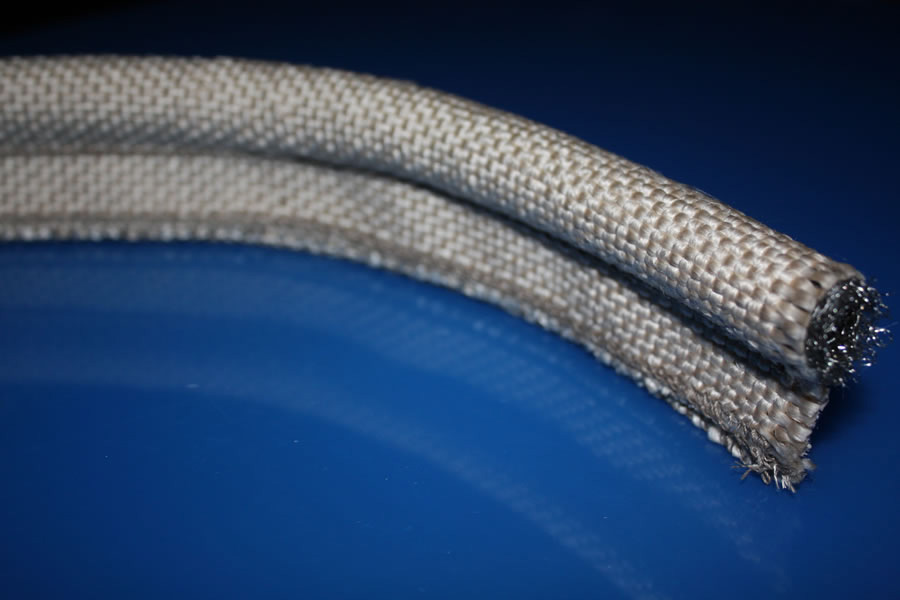

Tadpole gasket tape is designed with a compressible “bulb” and a flat “tail” that allows it to be securely attached to access doors, flanges, and inspection ports. Made from heat-resistant materials such as fiberglass and silicone-coated fabrics, this gasket can withstand the harsh thermal and chemical environments typically found in incineration systems. Its flexible construction ensures a consistent, tight seal, even when exposed to frequent thermal cycling and pressure changes.

By sealing critical points on the incinerator, tadpole gasket tape minimizes heat loss and prevents unfiltered air from entering or hot gases from leaking out. This containment is crucial for maintaining combustion temperatures and ensuring complete destruction of pollutants. A better seal also improves draft control and reduces the load on blowers and fans, further increasing overall system efficiency and reducing energy consumption.

Incorporating tadpole gasket tape into fume incinerator maintenance or upgrade plans is a cost-effective way to boost performance, ensure environmental compliance, and extend equipment life. By preventing energy waste and enhancing operational safety, this simple yet durable sealing solution helps facilities run cleaner, safer, and more efficiently.