Boosting Emission Control System Efficiency with Tadpole Gasket Tape

Emission control systems are essential for reducing harmful pollutants released from industrial processes, protecting both the environment and regulatory compliance. These systems often operate under high temperatures and corrosive conditions, making airtight seals critical to performance. One simple yet powerful component that enhances efficiency and reliability in these systems is tadpole gasket tape. Engineered for extreme environments, this high-temperature sealing solution helps minimize leaks, conserve energy, and maintain system integrity.

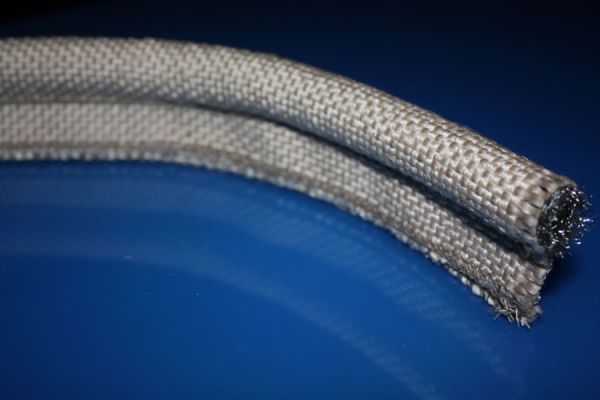

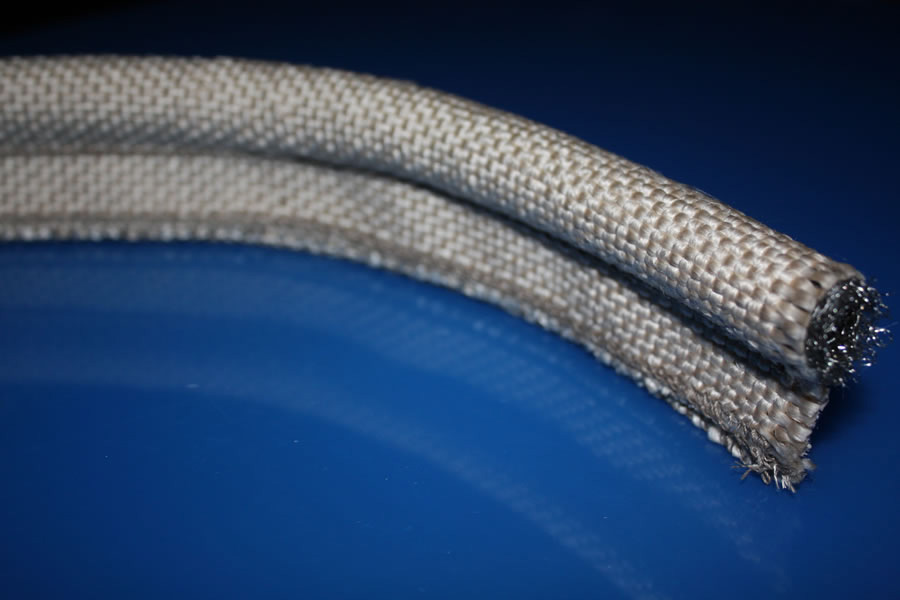

Tadpole gasket tape is uniquely designed with a rounded “bulb” that compresses to form a reliable seal and a flat “tail” for secure attachment to doors, flanges, ducts, or access panels. Constructed from materials like silicone-coated fiberglass or other heat- and chemical-resistant fabrics, the tape can withstand the harsh conditions found in scrubbers, thermal oxidizers, baghouses, and other emission control equipment. Its flexible design conforms to irregular surfaces, ensuring an even seal across high-use or maintenance-prone areas.

By sealing potential leak points, tadpole gasket tape prevents untreated gases from escaping and keeps outside air from diluting internal combustion or filtration processes. This enhances the system’s ability to efficiently capture or neutralize pollutants, maintaining consistent operational performance and reducing the burden on fans, heaters, or other auxiliary components. The result is lower energy usage, fewer emissions, and a more dependable compliance strategy.

For any facility running emission control systems, upgrading or maintaining seals with tadpole gasket tape is a smart investment. It helps ensure optimal thermal performance, prevents environmental leaks, and supports long-term durability of the equipment. In a regulatory landscape where performance matters more than ever, tadpole gasket tape delivers both efficiency and peace of mind.