Boosting Batch Oven Efficiency with Tadpole Gasket Tape

Batch ovens are essential for a wide range of heat processing tasks—curing, drying, aging, and heat-treating materials in controlled cycles. These ovens are designed for flexibility and precision, but their efficiency can be compromised by one simple factor: heat loss. One of the most effective ways to enhance thermal retention and performance in batch ovens is by using tadpole gasket tape. This specialized sealing tape helps maintain a consistent oven environment, leading to shorter cycle times and reduced energy consumption.

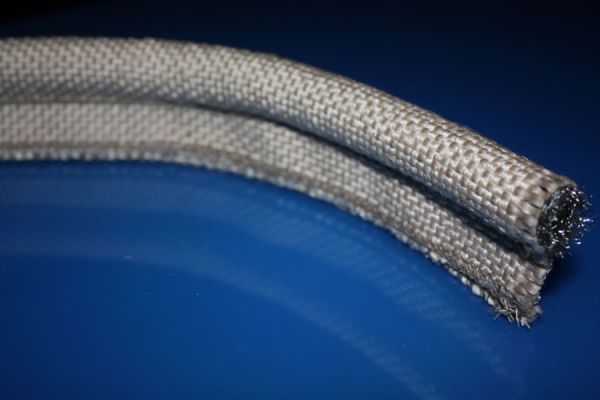

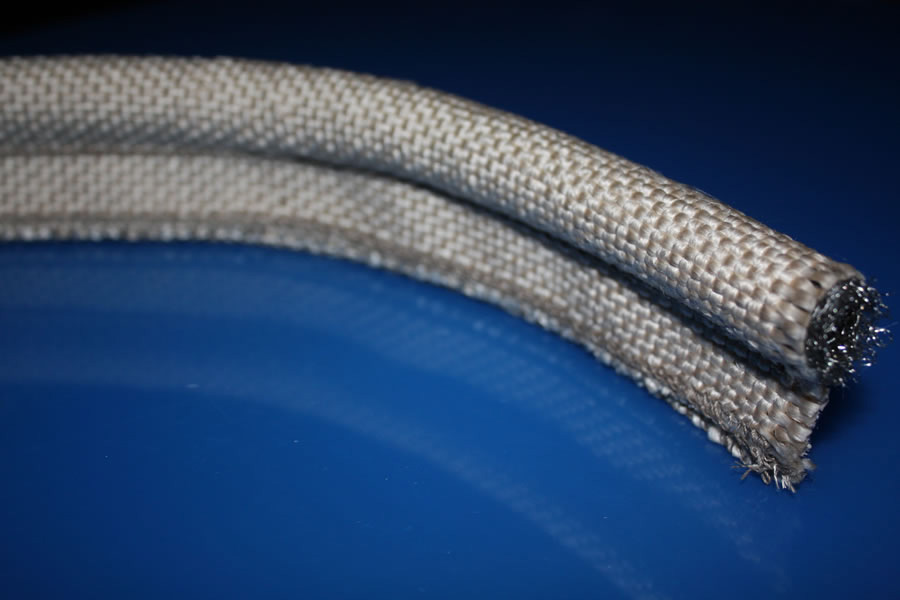

Tadpole gasket tape features a rounded “bulb” that compresses to create a secure seal and a “tail” that attaches to the oven frame. It’s made from high-temperature-resistant materials such as silicone-coated fiberglass or other engineered textiles, allowing it to perform reliably in the intense heat conditions of batch ovens. The tape is commonly installed along the oven door and access panel perimeters—areas where heat can easily escape if not properly sealed.

By creating a dependable thermal barrier, tadpole gasket tape minimizes temperature fluctuations inside the oven. This not only improves the consistency of each batch, but also reduces the workload on the oven’s heating elements and control systems. Maintaining tighter thermal control leads to faster warm-up times, more uniform processing, and longer equipment life—all of which contribute to a more efficient and cost-effective operation.

For manufacturers and facilities that rely on precise, repeatable thermal processes, upgrading or replacing worn-out seals with high-quality tadpole gasket tape is a smart and simple way to improve batch oven performance. It’s a small investment with big returns in energy savings, process reliability, and overall equipment longevity.